| |

The

hydraulic pulse interference test was initially developed for characterizing

petroleum reservoir permeability and hydraulic connection between

production wells. GeoSierra has modified and enhanced the equipment

and method for use in characterizing shallow groundwater sites and

to act as a quality assurance technology for both iron PRB and slurry

wall constructed systems. The first commercial application of the

hydraulic pulse interference test was by GeoSierra at its first

iron PRB installation at the Caldwell Superfund site in Fairfield,

NJ in 1997. Since that time the hydraulic pulse interference testing

equipment, procedures and interpretation software have been utilized

by GeoSierra at a number of iron PRB installations for both site

characterization and quality assurance testing to ensure the constructed

iron PRB does not impede groundwater flow. The

hydraulic pulse interference test was initially developed for characterizing

petroleum reservoir permeability and hydraulic connection between

production wells. GeoSierra has modified and enhanced the equipment

and method for use in characterizing shallow groundwater sites and

to act as a quality assurance technology for both iron PRB and slurry

wall constructed systems. The first commercial application of the

hydraulic pulse interference test was by GeoSierra at its first

iron PRB installation at the Caldwell Superfund site in Fairfield,

NJ in 1997. Since that time the hydraulic pulse interference testing

equipment, procedures and interpretation software have been utilized

by GeoSierra at a number of iron PRB installations for both site

characterization and quality assurance testing to ensure the constructed

iron PRB does not impede groundwater flow.

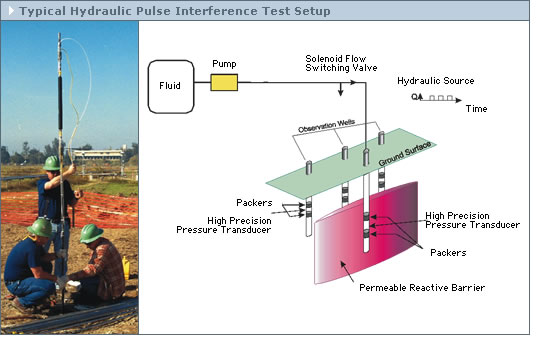

The hydraulic continuity of the PRB is quantified by pulse interference

tests, with pulse source wells on one side of the wall and high

precision receiver transducers installed in wells on the opposite

side. The test involves a cyclic injection of fluid into the source

well and high precision measurement of the pressure pulse in a neighboring

well. The time delay and attenuation of the hydraulic pulse enables

the hydraulic effectiveness and continuity of the wall to be assessed.

GeoSierra’s pulse interference testing method is also ideal

for the hydraulic characterization of complex flow systems, such

as fractured bedrock, braided stream and esker deposits. Being a

transient hydraulic test, transmissivity and storativity can be

determined, and hydraulic flow regimes can be clearly delineated.

Download

PDF (200 kb) Download

PDF (200 kb) |

|