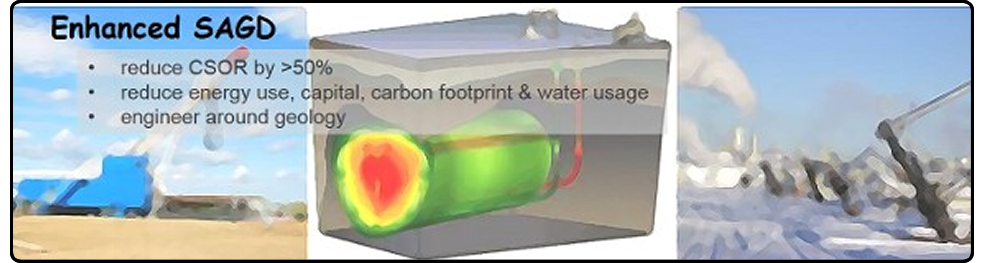

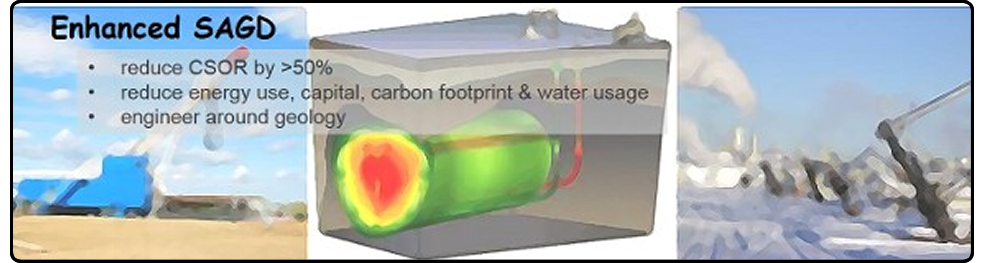

Conventional steam-assisted

gravity drainage (SAGD) involves a horizontal well pair typically spaced 5m

apart vertically with the injector well located above the producer well as

shown. The wells are connected

hydraulically during a steam

re-circulation phase, followed by the SAGD production

mode, i.e. continuous injection of steam

and the continuous

extraction

of liquids.

Performance of conventional SAGD can be significantly

impacted in formations with

low vertical permeability and interbedded

mudstone layers impeding vertical

drainage and hindering or delaying the

startup

phase.

The Azi-Frac horizontal open-hole stimulation method

installs vertical

propped planes from the injector well at

~50m spacing along the wellbore, thus hydraulically connecting

the injector

and producer wells. The vertical

propped planes orientated orthogonal

to the

injector wellbore are propped with a high permeable 12/20 garnet sand proppant.

The injector well is completed following the

open-hole stimulation with

a conventional slotted liner.

Reservoir simulations of conventional SAGD can be

highly unreliable due to the difficulty in estimating formation vertical

permeability under steam and its significant impact on SAGD performance. The

frac enhanced SAGD being virtually independent of formation vertical

permeability, enables reservoir simulations to be conducted with a high degree

of confidence.

+1 (770) 559-4429 info@geosierra.com

+1 (770) 559-4429 info@geosierra.com